A recent study investigated how effective oil-based coatings on the surface of food processing equipment are in preventing bacterial growth.

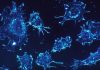

Food processing equipment is commonly made of stainless steel, due to its strength and relatively low cost. However, the minor scratches and grooves on the stainless steel surface from typical wear and use are an ideal breeding ground for bacteria to grow. These bacteria can also produce a biofilm that protects them from typical cleaning and sanitation methods.

The persistence of these bacteria can lead to cross-contamination of foods and food-borne illnesses, which are associated with industry and health care costs, morbidity and mortality. Therefore, preventing the bacterial attachment to the surface of food processing equipment is a valuable strategy to prevent the formation of biofilms.

SLIPs: A new class of surfaces

Slippery liquid-infused porous surfaces (SLIPs) are a new class of surfaces that have been developed and researched, but few studies have researched their application on food processing equipment. Essentially, these SLIPstrap a thin layer of oil at the metal’s surface to fill in the scratches and cracks to create a barrier to bacterial attachment.

A recent study published in ACS Applied Materials & Interfaces describes the work done by scientists in Canada and Egypt on developing foodsafe oil-based surface coatings (FOSCs) for preventing bacterial biofilms on food processing equipment. They tested their foodsafe oil-based surface coating on surfaces with different surface roughness and after regular wear and erosion from equipment use.

Rough surfaces encourage bacterial growth

The scientists found that the rougher the surface, the higher the rate of bacterial attachment and growth. Their results saw a reduced initial bacterial attachment with the use of FOSCs to decrease the surface roughness and a 1000 times reduction in overall bacteria levels. They also demonstrated the oil-coated surface’s ability to improve cleanability and removal of bacteria when washing with detergent.

The foodsafe oil-coated surfaces were also analyzed after regular surface wear and erosion. They observed that after wear, the remaining oil layer still covered the surface scratches and cracks to continue providing a physical barrier to preventing bacteria from attaching and forming biofilms. The scientists suggest that not only are these foodsafe oil-based surface coatings nontoxic, they are also low-cost and can be scaled to large food-processing facilities.

Promising results for use in food processing equipment

The scientists intend to continue researching and developing the optimal choice of foodsafe oil-based surface coating under a range of wear and erosion conditions for preventing bacterial adhesion and biofilm production. Ultimately, they hope to use this foodsafe oil-based surface coating method on food processing equipment to reduce the rates of food-borne illness and improve mortality rates.

Written by Maggie Leung, PharmD

References:

- wad, T. S., Asker, D., & Hatton, B. D. (2018). Food-Safe Modification of Stainless Steel Food-Processing Surfaces to Reduce Bacterial Biofilms. ACS Applied Materials & Interfaces,10(27), 22902-22912. doi:10.1021/acsami.8b03788

- Hunter, K. (2018, July 27). Cooking oil coating prevents bacteria from growing on food processing equipment. Retrieved from http://news.engineering.utoronto.ca/cooking-oil-coating-prevents-bacteria-from-growing-on-food-processing-equipment/